Unified Emissions Intelligence

Unify All Your Emissions

Data in a Single Platform

Gushr harmonizes data from drones, sensors, and satellites—transforming fragmented measurements into real-time visibility and compliance intelligence for energy operators.

Observe

Gain real-time visibility across all methane and flare data streams, no matter the sensor or asset, and detect emissions before they become a problem.

Analyze

Turn complex, heterogeneous sensor data into actionable insights using AI-driven analytics and advanced modeling for smarter operational decisions.

Act

Automate responses, optimize flare performance, and reduce emissions with workflows designed to improve safety and efficiency.

Research Meets Action

Transforming Data Into

Operational Intelligence

Our platform leverages cutting-edge mathematical models and AI to translate complex flare and methane behavior into actionable insights. Operators get real-time metrics to optimize performance, reduce emissions, and enhance safety.

Smarter Flaring, Safer Operations

Traditional flare monitoring is manual, fragmented, and prone to error. Gushr automates emissions monitoring and integrates data across all sensors, giving operators predictive insights that improve safety, optimize performance, and lower costs.

Monitor Assets

Reduce Emissions

Across Your Operations

Petroleum

Refineries

Gain real-time insights into methane and flare emissions across refining operations, ensuring compliance and optimizing flare efficiency.

Oil & Gas

Production Sites

Monitor wellheads, separators, and gathering systems to detect emissions early, improve safety, and reduce operational losses.

Natural Gas Processing Plants

Support compliance and sustainability efforts with real-time methane detection for energy providers.

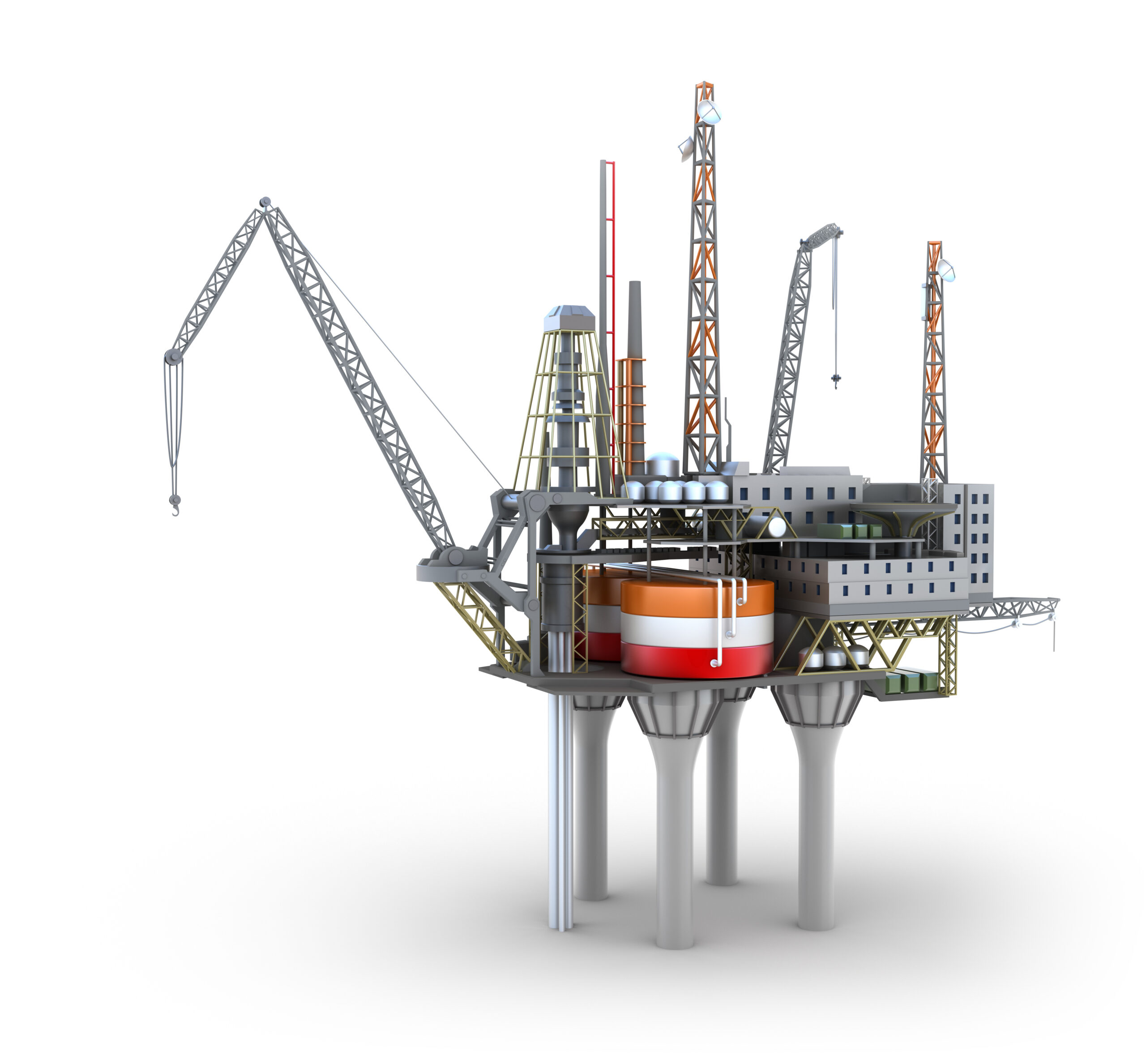

Offshore Oil Platforms

Collect and analyze emissions data in challenging offshore environments to maintain safety, efficiency, and regulatory compliance.

AI-Driven Emissions Modeling

Gushr uses aerial, sensor, and flow data combined with advanced computer vision and machine learning to predict methane and GHG emissions across your operations. By modeling complex flare and gas behavior, our platform helps operators make proactive decisions, optimize flaring, and reduce environmental impact.

Key Capabilities Include:

- Predict Emissions Hotspots – identify where methane releases are likely to occur before they impact safety or compliance

- Optimize Flare Performance – model gas behavior under different operational conditions for maximum efficiency

- Account for Environmental Variables – including wind, dilution, and atmospheric conditions

- Reduce Pollution & Soot – analyze combustion efficiency to minimize emissions

- Integrate Multi-Sensor Data – harmonize drones, cameras, satellites, and flow meters for actionable insight

Compliance

Safety and efficiency

The Gushr AI platform helps energy operators achieve sustainability goals while improving operational efficiency and safety. It is a powerful tool that can help energy operators reduce costs, improve worker safety, and protect the environment.

Reduce GHG Emissions

Regulatory Compliance

Worker Health & Safety

Operations Efficiency

Unified Sensor Data

Aggregate and harmonize information from drones, satellites, cameras, and flow meters into a single platform.

Optimize Flare Performance

Use AI and modeling to improve combustion efficiency, reduce emissions, and lower operational costs.

Predictive Risk Detection

Identify potential equipment or operational risks before they impact safety or compliance.

Real-Time Emissions Visibility

Track methane and flare activity continuously across all assets for immediate insight.

Latest Insight

Oil and Gas Rig Basics: Understanding the Industry’s Workhorses

Drilling rigs are the essential, massive machines that find and tap oil and gas reservoirs. From $10M onshore units to $1B deepwater ships, their cost and scale reflect the complexity of global energy access. Understanding rig count reflects market health.

API 521: Establishes flare sizing and relief conditions

API 521 defines how to size relief systems and flare equipment, tying process scenarios to relief loads and header hydraulics. Designing to the standard reduces safety risks and unplanned methane emissions, enabling better monitoring and actionable mitigation.

Colonial Pipeline: The Artery of U.S. Fuel Distribution

Colonial Pipeline, the 5,500-mile network moving 2.5 million barrels of fuel daily, remains a cornerstone of U.S. energy logistics. Its modernization under Brookfield signals a new era of resilient, digitally integrated infrastructure across America’s energy landscape