Technology plays an essential role in improving industrial systems and opening up opportunities for their evolution. This implies that traditional solutions must be open to change, and companies, through their engineering managers, must be willing to adapt and allocate the necessary resources. These decisions become even more critical when optimizing the production systems of energy sources.

An evident example lies in the oil and gas sector, where technology serves as an invaluable assistance tool for daily operations. In this industry, companies must embrace a strategy of continuous improvement and development, primarily driven by the enforcement of strict environmental regulations.

Among its most widely known operations, by both specialists and those outside the industry, is gas flaring. This process is directly linked to the associated gas generated during oil production and, in specific cases, in refinery facilities. To ensure the safe and controlled execution of these processes, these facilities must be strategically designed and appropriately located. Moreover, the availability of technology capable of supporting or substituting technical operations that demand higher precision is crucial.

Despite the use of technology in this sector for mitigating its impact, you might be wondering: Why do we still employ these processes instead of storing the gas? Is it possible to completely eliminate our dependence on fossil energy sources? How much gas is currently being flared worldwide, and what measures are being implemented? In the following sections, we will address these questions to offer you insights into the current state of affairs and a projection of how modern technology enables the mitigation of potential incidents and the reduction of environmental pollution.

Energy Dependency

The increase in energy consumption is closely related to economic development, population growth, and industrialization. In 2019, the global energy supply reached approximately 606 EJ (Exajoule), registering a growth of 1.27% compared to the previous year. The three primary energy sources were oil, natural gas, and coal. Specifically, oil and natural gas accounted for 50% of the total supply, while renewables (such as solar, wind, hydro, geothermal, and ocean) saw their share rise to around 5.2% in 2021, with an expected growth projection of up to 17.5% by 2030. Consequently, fossil fuels are projected to play a complementary role in the upcoming years as renewable energy sources experience significant expansion.

Under this scenario, flaring operations will remain a reality in the energy industry. Despite the targets set to achieve Net Zero Emissions by 2050, there are still engineering challenges to address in terms of design, construction, and management.

Why Do We Still Use Flaring Operations?

Gas flaring operations are executed during the well-drilling process in the quest for oil and at facilities involved in oil processing. The composition of this associated gas varies across geographic locations and typically comprises a mixture of different hydrocarbons. Methane is the predominant component, accompanied by smaller quantities of propane, ethane, and butane, alongside inert gases and water vapor.

Both flaring and venting operations act as disposal methods when the produced gas cannot be economically captured, processed, or transported. Furthermore, they are employed in cases during emergency situations and in well-testing or exploration activities.

While flaring and venting operations serve necessary purposes, they also carry distinct environmental and safety implications. Studies indicate that venting operations can be more damaging due to the release of methane, which contributes more as a greenhouse gas than other gases produced during combustion.

Size and Utilization of Flares

The practice of gas flaring differs according to the environmental regulations of each country. On the one hand, flare systems are prohibited from being situated in urban or natural areas where noise and emitted light could negatively affect the surrounding ecosystem. These restrictions aim to preserve environmental balance and minimize adverse impacts on flora and fauna.

On the other hand, when burning is mandatory, specific operating periods are established, which are defined based on the operational capacity of the flare. This implies that its usage is confined to controlled and predefined conditions, ensuring the efficient and safe regulation of gas flaring.

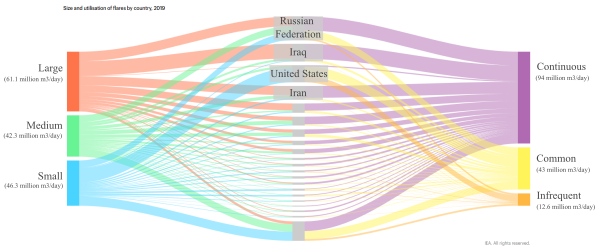

The capacity and size of a flare are specified by the volume of gas that needs to be released. Typically, categories are established using volumetric flow measurements, which can be defined as follows: small (< 0.03 Mm3/d, millions of cubic meters per day), medium (0.03-0.1 Mm3/d), and large (> 0.1 Mm3/d). In terms of the percentage of time during which burning is observed, flares can be classified as infrequent (<30%), common (30-85%), or continuous (>85%).

According to an article published by the IEA, it was estimated that “around 150 billion cubic meters (bcm) of natural gas was flared globally in 2019, as much gas as Japan and Korea together imported in the same year. Despite rising awareness of the problem, and a number of initiatives aiming to curb flaring, the amount of gas flared globally each year has been edging higher in recent years and the world is now flaring as much as it did ten years ago.”

This situation presents a significant challenge regarding natural resource waste and greenhouse gas emissions. Consequently, global efforts are underway to reduce flaring by focusing on enhancing infrastructure and promoting more sustainable practices.

Importance of Fast Response: Use of Technology

The design and management of flare systems entail significant risk due to the volumetric flow of gas vented or flared. In onshore infrastructures, it is essential to position flare systems away from the gas pipelines, while in offshore infrastructures, they must be separated from sensible control systems. Alarmingly, an estimated 54% of the total gas flaring occurred at sites within 20 km of pipelines, with some cases even at distances less than 500 meters. This proximity escalates the probability of incidents and failures, which can have severe implications for safety and the environment.

In response to these challenges, companies are implementing stricter safety measures, properly planning the placement of flare systems, and promoting technologies and practices that enhance the efficiency of gas combustion. Achieving these objectives necessitates the continuous monitoring of flaring and venting operations using modern technologies, enabling users to analyze data and make real-time decisions.

As an example, advanced monitoring and simulation tools are utilized to gather accurate data regarding the operation of flare systems, enabling the early detection of potential issues. These technologies not only facilitate the identification of problems but also allow for simulations and what-if scenarios to evaluate the impact of potential enhancements or modifications to the design and operation of flare systems. Such capabilities aid in optimizing system performance and mitigating associated risks.